Conveyors

Belt Conveyors

All MEGA belt conveyors and conveyor systems are engineered and manufactured around your unique application to ensure the best bulk handling solution possible.

Features

Size: 18” – 72” wide

Capacity: up to 8,000 TPH

Orientation: Horizontal & Inclined.

Standard troughed belt conveyors are comprised of conveyor belting that rides on heavy-duty troughed idlers. Idlers range in angles from 20°-45° and are securely mounted to a structural steel frame.

Applications

- Coal Handling for Power Plants

- Clinker and other raw materials for Cement Plants

- Woodchip and Bark Handling for Pulp/Paper Mills

- Sludge Handling for Process Applications

- Rail Loading / Unloading

- Bulk Warehousing of Granular Products

Gravity Roller Conveyor

Simplest of all conveyor types, they are very affordable. A series of rollers mounted on a side frame provides the rolling surface. When mounted on a decline angle, parts move by themselves. However, if using gravity conveyors for parts of different sizes and weights can be more difficult. you will need to control the speed and angle. Parts running into each other may cause damage. But compared with carrying parts from point A to point B, a gravity roller table is often a great starting point. It is a very simple productivity improvement. The system is highly modular in configuration and very easy to install.

Features

Size: 1” – 6” Dia

Width: 4” – 48”

Capacity: up to 750 Kg

Orientation: Inclined.

Standard gravity conveyors consist of rollers of different diameters and lengths. The selection is made by factoring in the size and the weight of the object to be conveyed.

Applications

- Automotive.

- Appliances.

- Food and beverage.

- Industrial.

- Pallet handling.

Chain conveyors

Chain conveyors use an endless chain to propel material through a trough, by pushing directly by the chain or by attachments to the chain. The chain runs over sprockets at either end of the trough. Chain conveyors are used to moving material up to 3 meters in size (10 ft.)

Chain conveyors are driven by a motor, and the material suspended on the pendants is conveyed. They are used for moving products down an assembly line and/or around a manufacturing or warehousing facility.

Features

Width: – 48”

Capacity: up to 750 Kg

Orientation: Horizontal, vertical & Inclined.

Our chain conveyor systems are typically a double strand configuration with the load positioned on the chains, however, multiple strand configurations are available.

Applications

- Automotive.

- Warehousing.

- Food and beverage.

- Industrial.

- Pallet handling.

- High-temperature zones.

Live Roller / CDLR

Chain-driven live roller conveyor systems are the most rugged of the conveyor range. they are ideal for transporting medium to heavy loads at controlled speeds for many applications. Typical loads are pallets, tires, drums, and totes.

CDLR’s can take a lot of abuse without damage. Rollers may be mild steel, galvanized, or stainless steel for special applications. Where impact loads are possible, thicker gauge roller material and upgraded bearings will be specified.

Features

Rollers Diameters: 1.9”, 2.5”, 3.5”, 4” and 5”

Effective widths: 3” -120” in any increment

Length: 1 ft. – 12 ft.

Reversible with speeds ranging from 5 -150 FPM fixed or variable

Built to order – highly customizable.

Orientation: Horizontal & Inclined.

Our chain conveyor systems are typically a double strand configuration with the load positioned on the chains, however, multiple strand configurations are available.

Applications

- Automotive.

- Warehousing.

- Food and beverage.

- Industrial.

- Pallet handling.

- High-temperature zones.

Screw Conveyors

Horizontal Screw Conveyors

These conveyors are the most widely used type of screw conveyors. Used to convey bulk materials from one part of a process to another, horizontal screw conveyors are available in a wide range of sizes, lengths, configurations, and materials of construction.

Inclined Screw Conveyors

Inclined screw conveyors operate from slightly above the horizontal position to 45-degrees from the horizontal position. As the degree of incline increases, conveying efficiency is reduced and horsepower requirements increase due to the effects of gravity and bulk material fall back.

Shaftless Screw Conveyors

Bulk materials discharged from centrifuges, filter presses, or mixers can easily be conveyed using a Shaftless Screw Conveyor. Our shaftless design provides a non-clogging conveying surface that allows difficult-to-convey materials to become easy-to-convey. The perfect solution for handling bulk materials with high moisture content is the MEGA Shaftless Screw Conveyor.

Vertical Screw Conveyors

Vertical screw conveyors are a very efficient method for elevating a variety of bulk materials at very steep inclines or completely vertical. MEGA considers any screw conveyor located on an incline over 45-degrees to be a vertical screw conveyor.

The compact design allows for the vertical screw conveyor to fit into almost any plant layout. With a minimum number of moving parts, the vertical screw conveyor is a cost-effective and dependable component of any bulk material handling process.

Features

Shaft Diameters: 1” to 5”

Augur Dia: 6” to 24” in any increment

Length: 1 ft. – 20 ft.

Built to order.

Applications

- Bulk conveying of grains and fodder.

- Minerals processing.

- Wastewater and sludge.

Motorized driven roller conveyor

MDR conveyor systems use motorized rollers mounted within the conveyor frames. Compact in size, quiet and safe these are driven with 24-volt DC power. These are speed controllable and these are driven by PLC systems that enable fast, and smooth package movement. Importantly, sensors and controls ensure packages don’t get damaged by crushing against each other.

MRD’s are a great choice for energy efficiency, low noise, and easy maintenance.

MDR conveyors handle a multitude of products such as:

- Packages

- Tote Bins

- Pallets

- Tires

- Cartons

- Any product that will move on a roller conveyor

Features

Conveyor frame width: 15” to 60”

Speed: 10 to 100 FPM (Feet/Min)

Voltage: 24 VDC

Roller pitch: 3” to 6”

Variable speeds with reversible option.

Applications

- Parcels and cartons

- Food & beverage.

- Consumer durable assembly stations.

- Distribution & warehousing.

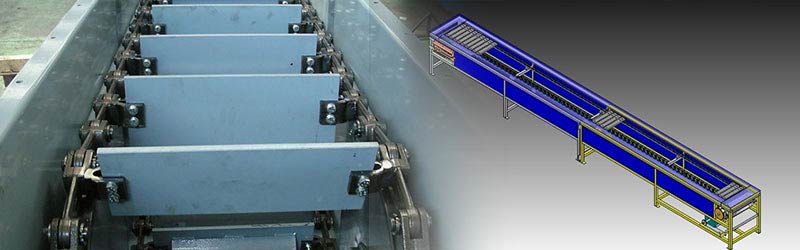

Slat Conveyor

These conveyors use a slat and chain system to move components along an assembly line. Steel panels are attached to the chain with special chain attachments, and the chain is driven by an electric motor and gearbox. They are used to deliver parts along the assembly line while the work is being performed. They are ideally suited to assembly stations where multiple assemblies are done.

The slat conveyor system also allows production assembly operators to work on one or both sides of the line. Fixtures can be added to the slats to enable parts to rotate 90, 180, or 360 degrees to facilitate better ergonomic access. During model change-overs, the tooling or fixtures can be modified or replaced, and the conveyor is re-used for another new application.

Features

Conveyor frame width: 12” to 108”

Speed: 10 to 60 FPM (Feet/Min)

Fixed and Variable speeds with reversible option.

Height adjustable legs

Any angle indexing movement from station to station

Applications

- Industrial assembly stations.

- Food & beverage.

- Distribution & warehousing.

- Cartons handling.

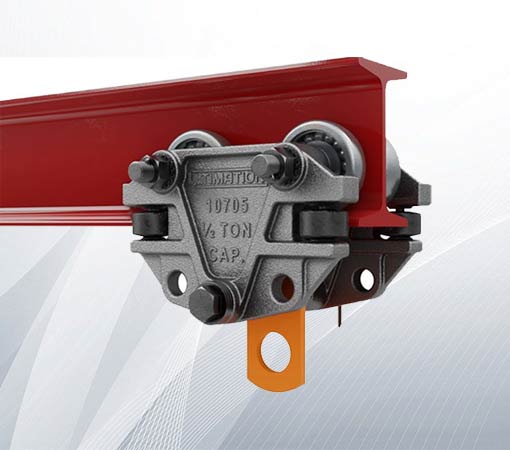

Beam trolley systems

The earliest conveyors are beam trolleys. They are simple to plan, install and use. They are the most affordable ways to move products efficiently. Because of this versatility, I-beam trolley applications include home workshop use, paint finishing lines and use in assembly plants. They are sometimes called monorail trolley track systems in factories.

Features

Weight carrying capacity: Up to 1 Ton.

Fixed and Variable speeds with reversible option.

Various types of hanging mechanisms.

Any angle indexing movement from station to station

Applications

- Industrial assembly stations.

- Finishing, painting & powder coating plants.

- High-temperature material handling.

- Blast room doors.