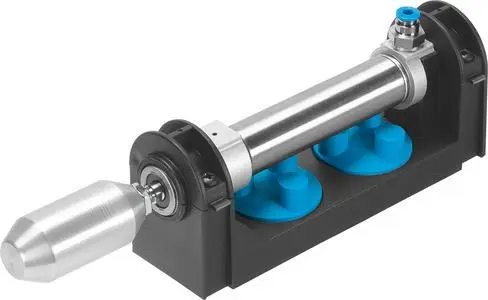

Pneumatic cylinder

The Pneumatic cylinder is a mechanical device that is used to compress the air to liner motion, where the object travels from one path to another path without deviating previous path. The movement of the piston can be used to perform various tasks, such as lifting, pushing, pulling, or rotating objects in a wide range of industrial applications. Pneumatic cylinders are commonly used in automation, manufacturing, transportation, and other industries where controlled linear motion is required.

Mega Ind Equipments is a leading Pneumatic cylinder manufacturer and supplier in UAE providing the diversional range of Pneumatic cylinders in UAE. we pride ourselves on delivering excellence in every aspect. Choose Mega Ind Equipment Products to match the quality of your needs and improve your industrial operations with our top-of-the-line.

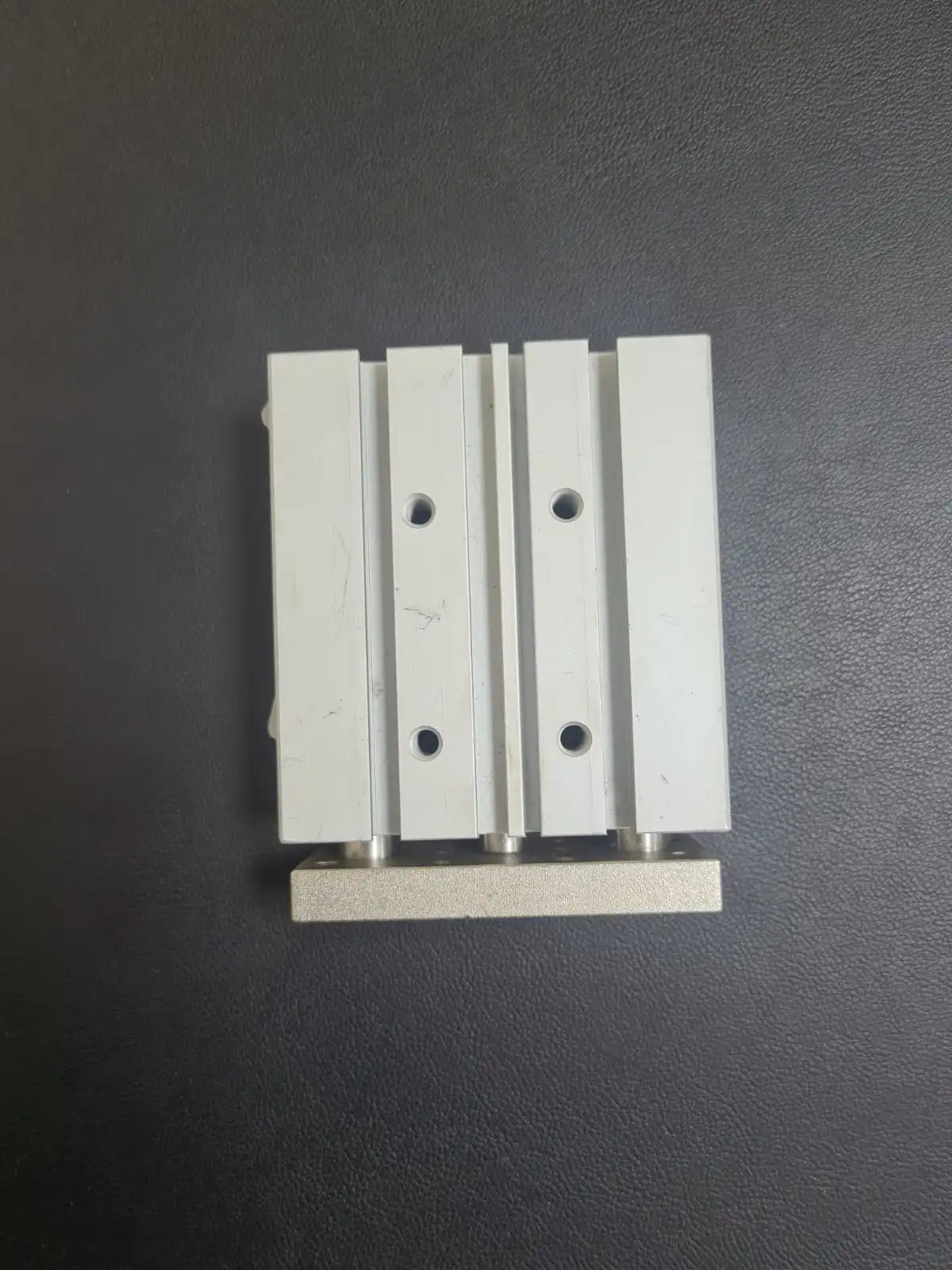

Telescoping cylinders

Telescoping cylinders, also known as telescopic cylinders or multistage cylinders, are designed to allow an extended stroke length at the same time as conserving a short-retracted period. Such cylinders use nested stages or sections that telescope in and out. The stages are connected by internal or external guides, such as guide rails or rollers, to help lengthen and retract effortlessly in a completely vertical movement.

Single-Acting Pneumatic cylinder:

The Single Acting Pneumatic cylinder only works in one position in stroke or out stroke and they cannot generate force in both directions like double-acting cylinders it is mostly used in internal engines such as Gasoline engines & diesel edginess. Single-acting cylinders much like the beating heart of a machine, comprise essential components that work harmoniously to achieve their purpose. Single-acting cylinders provide a practical and affordable option for applications that need movement in only one direction. However, it’s important to consider their operational constraints before using them.

Double Acting Pneumatic cylinder:

Double-Acting Pneumatic Cylinder Double-acting operates in an end-to-end position. One element is in stroke and another element is in outstroke to generate linear motions. One is for supplying compressed air to extend the piston, and another one is for exhaust air to retract the piston. When compressed air is supplied to the port in the hat connected to the opposite side of the piston, it pushes against the piston. Therefore, the piston elongates outwards of the cylinder, causing the production of linear motion in one direction. These elements are used in most of the applications as they ensure consistent and reliable operations, especially in those applications that call for accuracy in positioning and movement.

Why we are:

1.) Outstanding Quality: Our Expert Engineering team crafted the Pneumatic cylinder Accuracy and guaranteeing performance in any applications

2.) Wider Range: Our comprehensive selections of cylinders trailed to meet the diverse industrial needs from standard motels to customized solutions.

3.) Trusted Supplier: with a year of experience, we are the Trusted Pneumatic cylinder Supplier in UAE for all your industrial needs.

4.) Sustainability: is at the core of our values. We’re dedicated to environmental responsibility, and that’s why our pneumatic cylinders are meticulously crafted with sustainability in mind. Not only do they deliver peak performance,

5.) Delivery on Time: we understand the importance of time and how important Pneumatic cylinders are in industrial operations, we are committed to delivering on time

6.) Partnership: When you choose Mega and Equipment you are not just a customer you are a partner. We decided to build a long-term relationship in bast on trust and mutual success.

FAQ

Do you have a local presence or distribution network in the UAE for easy access to products and support?

Yes, we have established partnerships with the local community in UAE to ensure easy to access our products & support, we understand the importance of adopting the local market.

What is the Difference between a Pneumatic cylinder and vs hydraulic cylinder?

Pneumatic cylinders are easily compatible with gas like Air & Pure Gas, on the other hand, hydraulic cylinders are easily compatible with liquid media like Oil, Water, and synthetic types. Both products serve the purpose of generating linear motion in different operating principles.

What are the types of Pneumatic cylinders You Have?

There are three Pneumatic cylinders we deliver in UAE single, double Telescoping Pneumatic cylinders. Each of the applications uses specific industrial operations.

Difference between Single acting & Double acting Pneumatic cylinder

The single-acting cylinders only work in one end of the position, whether it is in-stroke or out-stroke. Otherwise, a double-acting cylinder works in an end-to-end position in & out stroke.

Who is the reliable Pneumatic cylinder supplier in UAE?

Mega Ind Equipments is the top Pneumatic cylinder supplier in UAE, offering all your pneumatic cylinders in one place. we pride ourselves on delivering excellence in every aspect.