Services

Mega Ind.Equip will providing you the complete industrial machinery service including over hauling of hydraulic cylinder, Hydraulic power pack and control panel & PLC’s as well and maintenance of all kinds of machines which make use of fluid power in construction industry, structural engineering ,fabrications, plant erection contracts, sales and supply of spare parts.

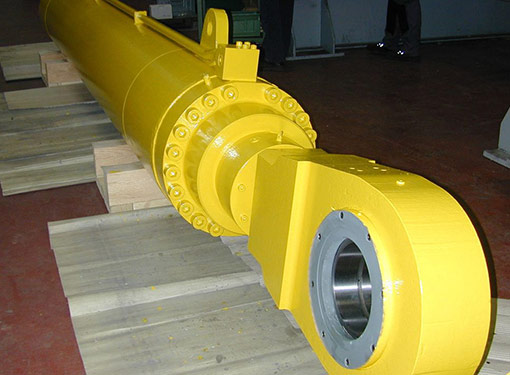

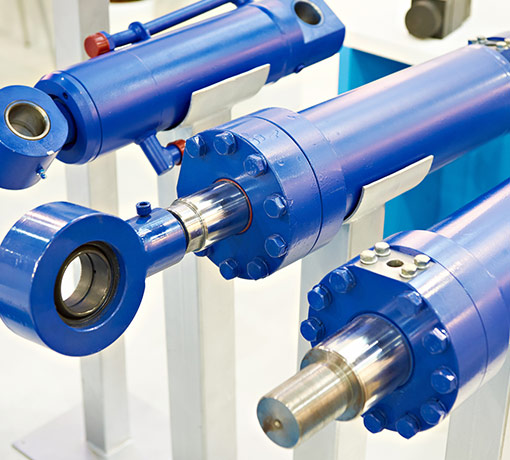

We offer services for hydraulic cylinder

Step of Hydraulic cylinder service

Step 1: Disassembly

Step 2: Inspection & evaluation

Step 3: Selecting & sourcing replacement parts & seals

Step 4: Designing components & running reliability simulations

Step 5: Machining, welding & reconditioning

Step 6: Sandblasting of barrels & other components

Step 7: Hydraulic cylinder rod restoration

Step 8: Reassembly

Step 9: Testing

Step 10: Painting & finishing

Step of Hydraulic cylinder testing after overhauling

Step 1: Ensure the cylinder is secured so that it is controlled

Step 2: Clean hydraulic fluid must fill both sides of the cylinder – do this through the ports;

Step 3: Connect all components – directional control valve, relief valve, ball valves and gauges

Step 4:Remove any air from the cylinder by using the directional control valve and stroking the cylinder numerous times

Step 5:Place the piston rod mid-stroke and close the ball valve

Step 6:Direct the fluid flow to the side of the cylinder where the rod is located

Step 7:Increase the setting on the relief valve until the pressure of the cylinder is seen on the gauge;

Step 8:Close both the ball valve and the directional control valve;

Step 9:Record the pressure of the cylinder from on both gauges and keep an eye on any changes.

We offer services for hydraulic power pack’s

Step of Hydraulic power pack (Compact power pack & customized power pack)

Step 1: General Maintenance – Inspect HPU for loose fasteners, hose fittings, damaged hoses, leaks, and worn electrical cables, repair as needed.

Step 2 . Filter Maintenance – The main pressure and return filter have a replaceable element that cannot be cleaned. Replace the filter after every 25 hours of operation. Replace desiccant filter when material turns from purple to pink

Step 3. Electric Motor – Periodic greasing is necessary on a frequently used HPU

Step 4. Lubrication – The swivel casters are equipped with grease fittings that must be lubricated annually

Step 5. Hydraulic Fluid – Replace hydraulic fluid if an unusual color or smell is noticed. Sample analysis may be required.

Step 6. Instrument Panel – Annual calibration is recommended on various gauges

Other services we offer

- Mobile hydraulic service

- Marine hydraulic service

- 2D Drafting Services

- 3D Modeling and 3D Mechanical Drafting Services

- Reverse Engineering (RE) Services

- Plastic Injection and Blow Molding

- Piping Design and Drafting Services

- Manufacturing Support and Process Planning Services

- Design for Manufacturing (DFM) Services

- Jigs and Fixture Design Services

- Specialized Mechanical Engineering Services